Automation is a marvel that has altered the techniques for creation, facilitating, speeding, and making progressively exact crafted by man.

Automation companies in Coimbatore is the innovation that utilizes control frameworks, such as rationale circuits or PCs, to deal with machines and procedures, which diminishes the requirement for human mediation. In the business, mechanization is applied to all segments, with the appearance of hardware, that has permitted to go from the unadulterated mechanics to the conceivable outcomes offered by gadgets and programmed controls.

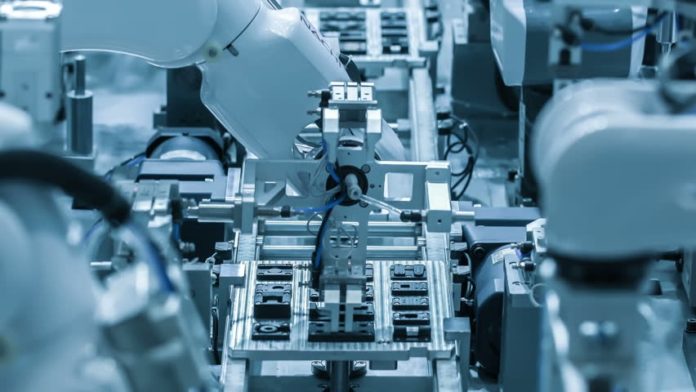

One of the mechanization parts is to apply autonomy, or the science that, through the investigation of savvy creatures, makes strategies that permit a machine (called robots) to perform explicit errands.

The alleged robot is controllers that let you perform explicit errands, from necessary activities such as welding to other progressively mind-boggling, such as painting, where you have to realize how to follow the shapes of each item. These machines are multifunctional, consequently controlled, reprogrammable, they comprise a progression of fragments associated by joints with various degrees of opportunity, fit to take, and move objects.

Denavit and Hartenberg have concentrated the imaginary parts of modern robots. They, as of now in 1955, set up a kinematic model rational to all controllers, utilizing suitable boundaries, for example, connect lengths and edges of joints through which it was conceivable to develop grids for computing the developments of mechanical arms. The investigation of this sort of electronic structure would open the path for techniques for figuring the direction effectively implementable on PCs.

The utilization of these mechanical controllers has changed much throughout the years, particularly with mechanization development. The principal application models date from the ’60s, because of Automation, an organization that structured the primary robot controller reasonable for welding focuses, a fundamental capacity; however, it was just the start. Until the ’70s, in any case, the inadequate utilization of these robots was likewise because they worked with pressure-driven gadgets and were subsequently not exact in their assignments.

A significant advance forward accompanied the plan and making of Stamford Arm robots from the University of Stamford and PUMA (Programmable Universal Machine for Assembly) consistently by Automation. These new robots, totally electric, were considerably more progressed than their ancestors. From that point forward, mechanical development has been rapid and consistent, with inventive recommendations every year.

Likewise now the mechanical technology has applications in numerous fields, not merely the business, which despite everything, remains the most significant part. There is, for instance, the home automation, or mechanical technology utilized in local conditions.

The bio robotics incorporates those robots used in the clinical field, automatic military technology, while not as created as in the motion pictures, utilized for the most part with observation and reconnaissance purposes among which there are, for example, automated airplanes called drones.

Space mechanical autonomy, in any case, regardless of whether it creates advances and strategies for the utilization of robots out by the environment, this field of apply autonomy has arrived at the favorable outcomes in areas outside the space research. Instances of these robots are the tests utilized in a few exploratory missions on the planets of the close planetary system.

Modern robots and how they work

It is in the view that the mechanical robot frameworks have been conceptualized. What’s more, this automated framework gives a lot of help to the mechanic. In the businesses where the cutting edge innovation has not been get and in those enterprises, the figuring out how to work the mechanical automation includes the heap.

There are two sorts of applications which are depending on the modern industrial automation course mechanical autonomy. These applications are Device amassing and infinitesimal clinical systems. These most recent and present-day innovation gadgets are very different than the other subclasses of conventional mechanical independence.

All the extra and additional parts and devices are made to satisfy the necessities of any assembling industry. This industry mechanical computerization framework works through convoluted and complex system designs that adjust to the business where it will be carrying out its responsibilities and work.

Modern mechanization robots are utilized to make exceptional items. It lessens the expenses of work, and it makes results of the same quality reliably. In the present-day period, many significant businesses utilize modern robots since it encourages the laborers to carry out their responsibility in the sheltered condition.

Modern mechanization mechanical autonomy, its segments, and its capacities

It has been said that modern computerization robots improves the quality and fitness and assembling for the producer. There are some different capacities and highlights to glance forward in the mechanization framework. Its guideline includes climate interfaces and sensors. This mechanization framework has likewise, security highlights. Every one of these highlights is connected with the territories in the business.

Extra parts likewise make up this mechanical apply autonomy mechanization ky frameworks. These minor and little parts are seen as small yet essential in making the framework run. The automated controller is known as the optional element of the framework. It is a mechanical arm, and it gives the development to different pieces of the electronic structure. The controller is an entirely adaptable segment or a portion of the frame.

Kinds of movements for the mechanical automation robots

Modern robots move about one way and various headings. One development is called a highlight point development, and the other event is called straight-line growth. In highlight point, development robots are made to move one bright spot to another clear place. Furthermore, in straight-line development, the robots move ahead.